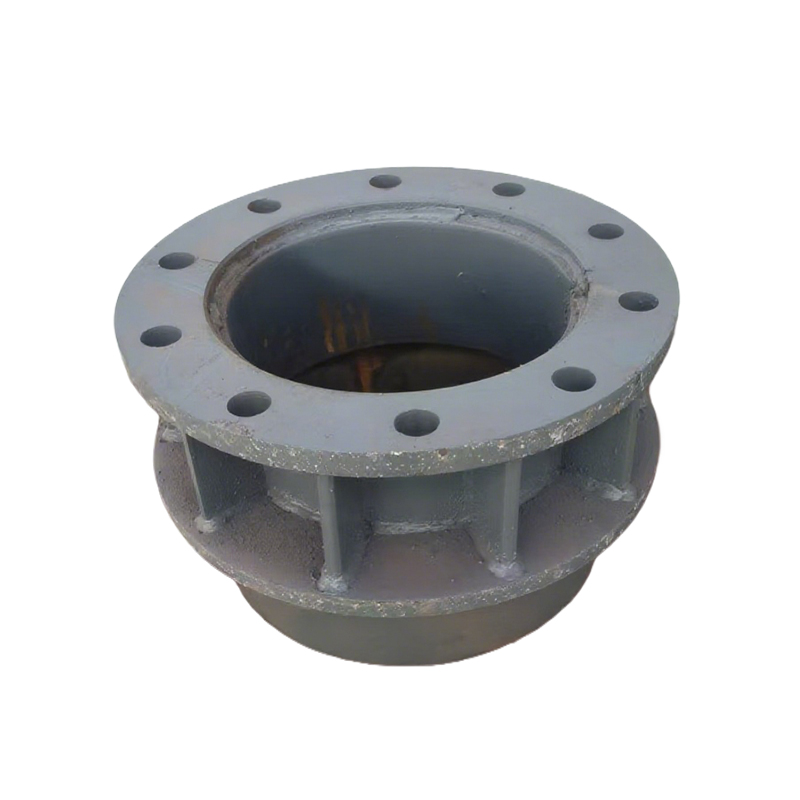

The length, width and height ratio of the outer shell must be reasonable to avoid local stress concentration caused by pressure overlap, thereby reducing the explosion resistance performance.

- +86-18919169590

- 319986510@qq.com

- South of National Highway 109, Baichuan Village, Xihe Town, Yongjing County, Linxia Prefecture, Gansu Province